Milestones

Any mention of the name Picanol, immediately brings up the thought of weaving machines. For over eighty years, Picanol has been a worldwide pioneer, and today, we are one of the leading weaving machine manufacturers in the world.

400,000th weaving machine in Ieper

In October 2023, Picanol achieved a new milestone with the production of its 400,000th weaving machine in Ieper, Belgium. This is a new high point in Picanol's rich history of production, which started in Ieper.

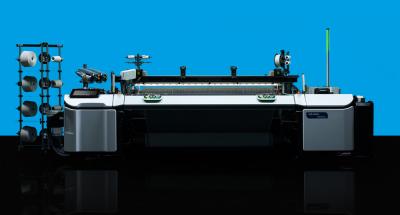

Launch of new rapier machine – the Ultimax – at ITMA 2023

In June 2023, Picanol launched its latest high-tech rapier weaving machine, the Ultimax, at ITMA 2023 in Milan (Italy). The world premiere of this all-new and revolutionary rapier weaving machine was the eye-catcher at the Picanol booth. The Ultimax focuses on three main benefits: ultimate performance and high-quality output, readiness for the sustainability requirements of tomorrow, and the greatest ease of use thanks to a maximum level of digitization. In addition, the classic Picanol exterior design of the machine has been radically disrupted in order to make it clear from the outside how revolutionary the Ultimax is on the inside.

Transaction involving Picanol Group and Tessenderlo Group

Picanol Group became a business unit of Tessenderlo Group with effect from January 1, 2023. This transaction simplified and increased the transparency of the group structure of both companies, into a single industrial group, with a single stock exchange listing and a single board of directors. As a consequence, Picanol is part of Picanol Group, which in turn became a business unit of Tessenderlo Group (Euronext: TESB – www.tessenderlo.com).

Virtual launch of the Connect generation weaving machines

In October 2021 Picanol has introduced its latest generation of airjet and rapier weaving machines, which have been called the “Connect” generation. These new generation weaving machines focus on connectivity and an increased level of data availability.

Picanol introduces PicConnect: the new online platform offering digital services

With PicConnect, a new fully digital platform, Picanol is offering a wide range of features, from industrial IoT to service-related applications. The platform is cloud-based and it allows connecting the Picanol weaving machines to the platform in order to leverage its full extent of possibilities. In October 2021, Picanol presented PicConnect virtually to its worldwide customers.

Virtual launch of TerryPlus-i

In september 2020 Picanol unveiled a new airjet weaving machine: the TerryPlus-i. The new TerryPlus-i was presented during a virtual launch show. With this launch, Picanol sets a new benchmark in terry weaving.

100,000th rapier weaving machine in Ieper

In May 2020, Picanol realized another impressive milestone when its 100,000th rapier weaving machine rolled off the production line at its plant in Ieper, Belgium. Picanol is also celebrating 45 years of manufacturing rapier weaving machines in 2020.

Picanol launches OmniPlus-i at ITMA Barcelona

In June 2019, Picanol has launched its newest airjet weaving machine, the OmniPlus-i, at ITMA Barcelona. With the introduction of the OmniPlus-i, Picanol set a new benchmark in airjet weaving machines.

Picanol Group celebrated its 80th anniversary

On Saturday 18 June 2016, Picanol Group celebrated its anniversary with a festival for all employees and partners at our premises in Ieper.

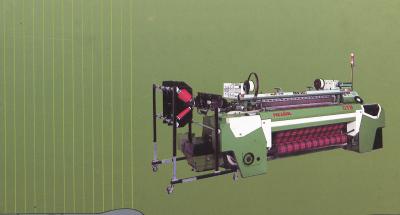

New weaving machines

In 2015, Picanol celebrated the 40th anniversary of the production of rapier weaving machines with the global launch of its new OptiMax-i rapier machine, the fastest industrially produced rapier weaving machine in the world. Picanol also launched two new weaving machines for the weaving of terry cloth: the TerryMax-i (rapier) and the TERRYplus Summum (airjet). Picanol is the only machine manufacturer to offer both rapier and airjet technology for terry cloth weaving. In November 2015, Picanol successfully participated in the 17th edition of ITMA in Milan, the most important four-yearly textile machinery exhibition in the world. Pleasingly, the new Picanol machines were received with considerable acclaim.

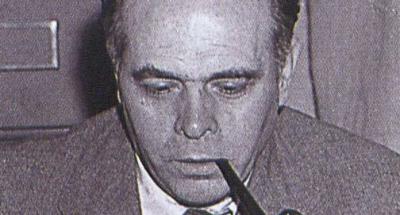

Luc Tack Manager of the Year

Luc Tack, managing director of the Picanol Group, has been chosen Manager of the Year 2014. The award, an initiative of the Flemish business weekly Trends, is being presented this year for the 30th time. The winner was selected by a jury of entrepreneurs, specialists and journalists in combination with online voting on the Trends website. Luc Tack, who was nominated for the third time in a row, follows Atlas Copco boss Ronnie Leten. ‘The jury singled out Luc Tack for his daring, ambition and strategic vision,’ explained jury chairman Luc Vandewalle. ‘Thanks to his outstanding management decisions Luc has managed to create renewal and growth at Picanol. Furthermore, with his achievements at Picanol he is a worthy successor to recent winners who have all been exemplary in the consistency, soundness and stability of their management.’

Opening new test area and training center

On 11 September 2014, Picanol inaugurated its new training center and new test area in Ieper in the presence of Mr. Geert Bourgeois, Minister-President of the Government of Flanders. Since improving the competitiveness through further productivity and quality improvements and targeted investments is a top priority, an investment program for an amount of 17.5 million euros in Ieper was approved in 2013. This investment plan includes the new test area for weaving machines, the new training center and the purchase of several production machines.

Picanol Group invests

In 2012, Picanol Group invested in the further expansion of its global sales and services network, including a new headquarters in India and a new office for Picanol of America.

Picanol celebrates @ ITMA Barcelona

At the four-yearly ITMA textile machinery exhibition in late September in Barcelona, Picanol celebrates its 75th anniversary with the introduction of two new products: the new high-end airjet weaving machine OMNIplus Summum and the positive rapier weaving machine (for very wide fabrics up to 540 cm).

300,000th weaving machine in Ieper

Early June saw the 300,000th weaving machine pass the end of the production line since production first commenced in Ieper, Belgium.

New rapier weaving machine

In March, Picanol launched a new rapier weaving machine, the OptiMax. Also in 2007, the GT-Max is launched. Production of this machine started beginning 2008 in Suzhou.

New OMNIplus 800

In April, Picanol launched the airjet weaving machine OMNIplus 800. With this weaving machine, Picanol Group set the standard for profitable airjet weaving.

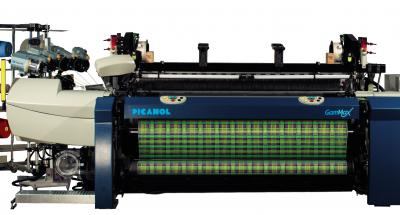

Introduction of GamMax

In November 2002, Picanol launched the GamMax-rapier weaving machine. The GamMax was equipped with a whole range of technological innovations. This new type 190 was designed to reach a speed of 650 weft insertions per minute.

Introduction of the OMNIplus

The OMNIplus airjet machine was introduced as the successor to the Omni, again using direct drive switched reluctance technology. Further application of electrical drives (for cloth batching and selvedge units) permitted even more flexible production. A type 190 OMNIplus machine achieved a speed of 1,100 weft insertions per minute.

Gamma rapier weaving machine

Picanol launched the Gamma rapier weaving machine. Initially, the machine was driven by a clutch/brake-unit. However, in 1999, it received a direct drive switched reluctance engine. The engine was dubbed SUMO Super Engine (Sumo through its ability to shift a large weight very quickly). The application of this technology represented a new milestone in the electronic control of weaving machines, as the machine speed can be varied during the weaving process. The Gamma is also equipped with the Quick Style Change system, and reaches a speed of 600 weft insertions per minute.

Expansion in China

Picanol further expanded in China. With the establishment of the joint venture Suzhou Picanol Textile Machinery (STM), 60 % owned by Picanol, Picanol started producing textile machinery in China.

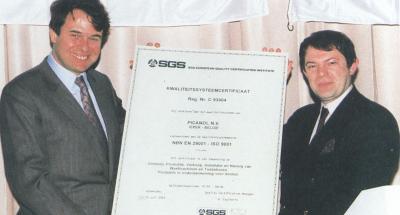

ISO9001-certification

Picanol was the first weaving machine manufacturer to obtain the ISO9001-certification in July 1993.

Quick Style Change system

Picanol introduced a new airjet generation in the early nineties. The Delta and Omni airjet weaving machines both used this technology and were equipped with the unique Quick Style Change system, which enables a total style change in less than 30 minutes by 1 person.

PAT with microprocessor technology

In 1985 at the ATME-Greenville, Picanol introduced the PAT airjet weaving machine with microprocessor technology. From a central computer, it became possible to communicate in two directions with the microprocessor of both machine types.

Breakthrough

At ITMA in Milan, Picañol was the first to show an airjet and rapier weaving machine monitored and controlled by microprocessor technology. The GTM rapier symbolized a breakthrough in the electronically controlled, shuttle-less rapier weaving machine industry.

Presentation PAT

By 1980, the revolutionary PAT weaving machine was developed, using the airjet insertion technology. The PAT was presented at the ATME exhibition in Greenville.

Presentation of PGW

In 1975, the company presented the PGW at ITMA Milan. The PGW was the first Picañol shuttleless weaving machine and used the new rapier insertion technology.

Introduction of the MDC

At the ITMA exhibition in Paris, Picañol surprised the textile industry with the introduction of the MDC, the world's first electronically controlled shuttle weaving machine.

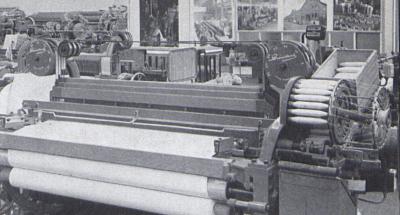

Investing in new production halls

The company invested in new production halls. An automatic foundry and new assembly line, having a capacity of 10,000 shuttle machines per year, were built outside the city center of Ieper.

Presentation of the President

At ITMA in Lille, Picañol presented the President, the automatic weaving machine with which Picañol conquered the world. More than 160,000 President Machines were sold, making the name of Picañol known and respected throughout the weaving world.

The beginning

In 1936, the Belgian industrialist Charles Steverlynck set up the company Weefautomaten Picañol NV. The first weaving machine was based on a design from the Spanish engineer Jaime Picañol.