PicConnect

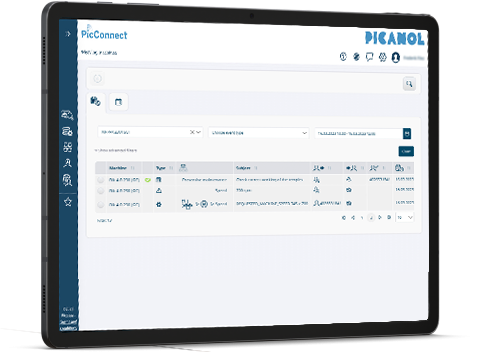

Picanol is proud to be “Driven by data”, and as such it has set itself the goal of tackling the next industrial revolution for its customers with the launch of PicConnect.

With PicConnect, a new fully digital platform, Picanol is offering a wide range of features, from industrial IoT to service-related applications.

PicConnect is a web-based application that can be accessed through a web browser on any device and it functions as the gateway to all Picanol’s digital services. The platform is cloud-based and it allows connecting the Picanol weaving machines to the platform in order to leverage its full extent of possibilities.

Welcome to the era of intuitive weaving

PicConnect enables weavers to quickly react to changes in the weaving room, and it will have an immediate impact on the performance of the weaving machines. It will not only change how weavers interact with their machines but also the way they interact with Picanol. For this reason, Picanol can boldly state that PicConnect is bringing weavers into the era of intuitive weaving.

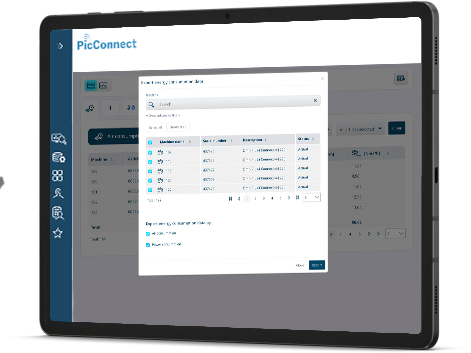

Webshop PartsLine

The new webshop for original Picanol spare parts, PartsLine, is a cornerstone of PicConnect. PartsLine offers a seamless online shopping experience, covering everything from quotations to reviewing orders and invoices.

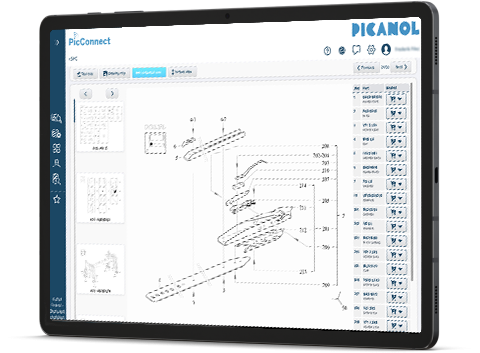

eSPC

The spare parts catalog (eSPC) shows the relevant catalogs for your installed base. The high-resolution drawings make it possible to easily find back specific parts.

Baskets of spare parts can be compiled and ordered in PartsLine, our webshop for original Picanol spare parts

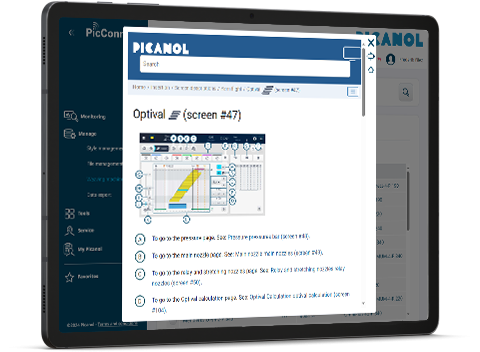

Machine manuals

With our intuitive digital platform, all the essential details about your machines are just a few clicks away. Consult the specific documentation of your weaving machines, such as the machine manuals or the electrical wiring diagrams.

Production monitoring

In the Production monitoring application, it is possible to track the production of the weaving machines. Real-time monitoring of the machine status enables the weaver to react quickly with regard to operational tasks and increase overall efficiency. The historical data, graphs, and tables provide the hard data to pinpoint exactly where action is needed.

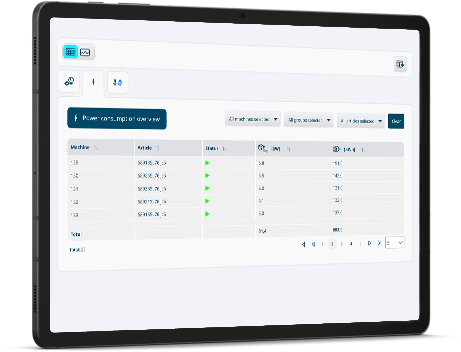

Energy monitoring

The Energy monitoring application keeps an eye on the energy consumption of the machines. In the case of airjet machines, also air consumption is monitored. It gives a better insight into the total energy flow in the weaving room, helping to reduce the overall energy costs and to adhere to the Picanol principle of “Sustainability Inside”.

Data export (API)

Data such as production and energy figures can be exported from PicConnect. Periodical exports can be planned to have access to your data when you need it. Or you can go one step further, and seamlessly integrate your machine data into your systems by leveraging our API.

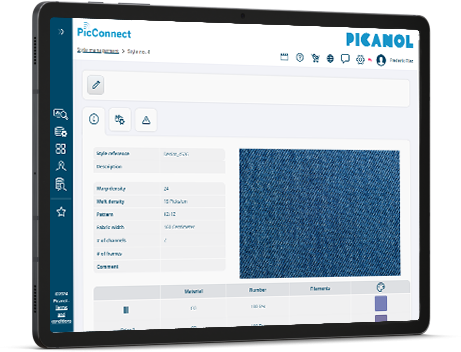

Style management

PicConnect offers a range of tools to help you manage and optimize styles and settings. Style management is used to create a library of styles and store all the relevant information regarding each style. Master settings can be linked to each style to support/optimize style changes. These settings are visualized using the setting editor, where settings can be changed or compared, which ensures the machines are all using the optimal settings.

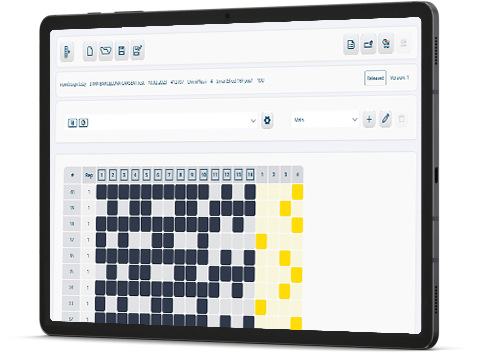

Pattern editor

The Pattern editor allows to create or edit designs for Picanol weaving machines. Complex patterns can be designed intuitively, and directly transferred to the machines.

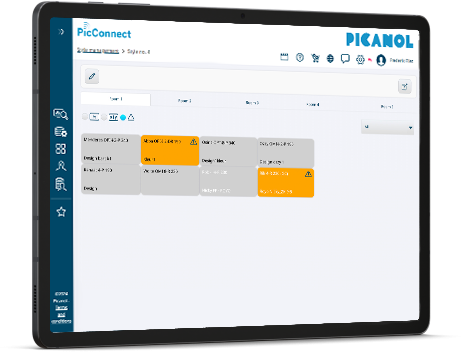

Alerting

The Alerting functionality allows to configure alerts for a wide variety of machine parameters such as production performance, energy consumption or machine settings. Being aware of deviations early enables taking decisive actions swiftly. Alerts can also be created to monitor style-specific thresholds, for example on air consumption, stop levels, or machine settings.

Preventive maintenance

PicConnect allows you to design, execute and monitor a preventive maintenance plan. The overview of scheduled tasks across machines can be used for planning purposes and spare parts stock management. The prescribed Picanol maintenance plans can be imported and followed up, with the aim being to maximize the uptime of your machines.

Logbook

The Logbook gives an overview of everything that has happened on the machine, from completed maintenance to setting changes. It can be used to perform analytics or understand how one works with the machine.

"How it works" videos about PicConnect

Discover our “How it works” videos about PicConnect in which Frederik Filez (Business Developer) explains the possibilities available in PicConnect, our online platform that centralizes all of our digital services.