R&D internship and thesis opportunities

At Picanol R&D, we believe that we can help you to grow. We will assist you in terms of defining the subject of your thesis by talking about your interests and aligning them with our expertise. Hence, we will be able to offer you a project that will not only suit you, but also one that you will be passionate about.

We have listed a number of topics and skills related to the Picanol R&D activities. You can review these themes to ascertain whether they align with your interests and, if so, we invite you to come and have a chat with us! Together we can define your ideal internship or thesis subject.

Proposed subjects

Motion control and optimization

Description

Picanol’s weaving machines consist of several reciprocating mechanisms with strongly varying inertia. These mechanisms are typically coupled to one or more drive motors. Work in this research field aims to drive these mechanisms at high speeds, while meeting stringent boundary conditions in an energy-friendlymanner.

Your task

You will help to set up system simulations and/or measurements that provide insights into challenging control problems. Together with colleagues, you will set out alternative, optimal control scenarios.

Skills and Tools

- Control engineering

- Matlab/Simulink

- Labview

Yarn insertion systems

Description

Manipulating yarns is a core competence for Picanol; with yarn speeds reaching up to 100 m/s and accelerations over 4,000 m/s², this represents a continuous field of research. The yarn propulsion systems of the weaving loom can be either reciprocating mechanical clamps or a jet of air surrounding the yarn and pulling it forward. Work in this research field aims to increase the speed of the insertion while keeping control over the yarn behavior and minimizing the forces acting on the yarn in order to obtain good quality fabric.

Your task

You will help in terms of designing, conceiving and studying mechanical, electromechanical or pneumatical systems that contribute to an improved and better performing yarn insertion system.

Skills and Tools

- Interest in mastering highly dynamic processes that are often of a stochastic nature.

- Multidisciplinary skills in mechanics, electromechanics, pneumatics and/or process control.

- Tools to understand and improve the insertion process, such as high speed cameras and measurement systems.

Drivetrain and structural design

Description

The weaving machine consists of drive groups that require a reciprocating movement of components. The drivetrain that connects the drive motor to the load needs to be designed in an optimal way in order to achieve the desired reciprocating movements, while withstanding the high forces related to these movements. Work in this research field aims at designing the drive train and machine structure to optimally transmit the drive forces to the load, thereby ensuring possible vibrations to the surroundings (noise, ground forces) are kept as low as possible.

Your task

You will help in designing, conceiving and studying drivetrains and related components and/or structural machine parts.

Skills and Tools

- Interest in machine drivetrains and/or structural machine design.

- Skills in mechanical design or analysis on components such as gears, bearings, cams, machine structure, etc.

- Measurement systems to perform vibration and noise analysis.

- Matlab-based tools for motion law design, component lifetime.

- Calculations, etc.

Sensors and signal processing

Description

Picanol’s highly dynamic weaving machines process textile into woven fabric. The yarns, the weaving process itself and the fabric have a stochastic nature. For this reason, performant detection systems (optical, piezo, strain, etc.) are needed to safeguard the quality throughout the weaving process. Work in this research field aims at designing sensors that are capable of capturing and evaluating yarn behavior, yarn tension, and fabric formation related parameters. Due to the high speeds involved, such sensors require both performant hardware and processing algorithms.

Your task

You will help in terms of designing, conceiving and studying sensors for the weaving machine.

Skills and Tools

- Interest in sensor design and/or processing algorithms.

- Skills in optics, sensor technology and/or signal processing.

- Measurement systems to perform measurements on existing or new sensors.

- Data processing tools, both offline and online – Matlab.

Textile research

Description

Picanol’s highly dynamic weaving machines process textile yarns into woven fabric. The yarns, the weaving process itself and the fabric have a stochastic nature. An in-depth understanding of the weaving process is necessary in order to determine the requirements for the machine and to find optimal settings to produce the highest quality fabric. Work in this research field aims at measuring and observing the weaving process and its parameters with two main purposes: obtaining a better understanding and evaluating the textile performance of the loom.

Your task

You will assist or perform weaving tests. You will then interpret data from such tests and monitor a proper setup for the experiments.

Skills and Tools

- Interest in the weaving process.

- Skills in textile technology and/or data processing.

- Measurement systems to perform measurements on yarns and machine components.

- Data processing tools, both offline and online – Matlab.

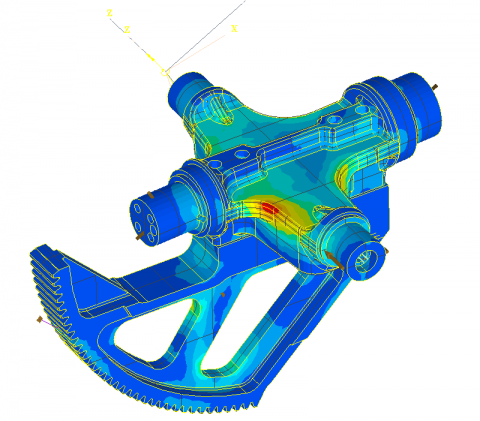

Simulation and measurement

Description

Picanol’s weaving machines are pushing the technical boundaries in many domains. To this end, computer aided simulation tools are essential if we want to obtain improved and better performing products. This is because they enable us to understand and improve the behavior and performance of the machine. Work in this research field aims at creating digital models of (parts of) the weaving machine to perform various forms of analysis and optimization. These simulations are often validated by measurements.

Your task

You will perform simulations in a specific domain of interest (thermal, mechanical, flow, etc.) to obtain a better understanding of problems or opportunities of the loom. You will perform or assist in measurements in order to validate digital models or to understand phenomena that cannot be modeled in an accurate manner.

Skills and Tools

- Interest in machines and their behavior.

- Skills in measurement and/or simulation in one of the following domains:

- Mechanical simulation (stress, strain, modal, etc.).

- CFD.

- Thermal simulation.

- Topology optimization.

Big data

Description

Many Picanol weaving machines are installed worldwide in a wide variety of working conditions. This means a massive amount of data is generated from the sensors and control systems it has onboard. Recent developments have opened up the possibility of harvesting this data remotely. This can create new opportunities for Picanol since it allows us to gain better and more in-depth insights into the performance of the machine in real conditions. Work in this research field aims to use this data to translate it into a better machine and an improved machine control design.

Your task

You will perform data analysis on large data sets with the aim of finding trends, verifying hypotheses and/or creating models. You will help to develop tools to visualize data in an easy way, allowing fast and easy follow-up.

Skills and Tools

- Interest in machines and their behavior.

- Interest in data processing and statistical analysis.

- Familiar with tools such as Python, R, Matlab, Azure, PowerBI

Interested? Let us know!

Interested in one of the subjects above or would you like to propose your own subject?

If so, let us know and we will do our best to define your internship or thesis together.

Contact us via stages@picanol.be.

Testimonials

Cédric Ally

MSc Electromechanical Engineering (Control Engineering and automation), UGent

“My master’s dissertation involved a study of the energy flow in the electromechanical drivetrain of airjet weaving

machines. I was able to put my knowledge of modeling, energy conversion and control engineering into practice. Therefore,

working on a master’s dissertation in cooperation with a company bridged the gap between my studies and working life.

The Picanol team members of the research project, which my dissertation formed part of, were always happy to share thoughts and provide guidance throughout the measurement sessions.Outside of work, the trainees are immediately included in activities, after-work drinks, etc. The young team is fully aware of the importance of positively integrating the newcomers.

In summary, I would really recommend a master’s dissertation in cooperation with Picanol to anyone. As soon as I completed my master’s dissertation, I was given the opportunity to work as an R&D Junior Engineer at Picanol. Clear proof that this is a great place to do your dissertation."

Robbe Moerman

Mechanical Design and Production Technology, Odisee Technologiecampus Gent

“During my 15 weeks internship, I researched the possibilities of a modern interpretation of a weaving technique used on older shuttle looms; specifically on a Picanol OptiMax-i gripper loom. A first prototype was built and tested, which proved the viability of this weaving principle.

This internship gave me the opportunity to use my creativity and further develop my designing skills. I met a lot of great colleagues from different fields who were more than willing to help and assist wherever possible. When I reflect on my internship, I always think of the welcoming and friendly-yet professional atmosphere in R&D.

I’ve accumulated really valuable knowledge and good contacts who I can keep in touch with in my profession as a R&D Designer at Picanol."